產品中心 >

產品中心 >

| 1. Ceramic core wire wound construction. |

| 2. No batch to batch variations in inductance |

| 3. High Reliability due to ceramic wire wound construction. |

| 4. High frequency application. |

| 5. Small footprint as well as low profile. |

| 6.100% Lead(Pb) & Halogen-Free and RoHS compliant. |

| 7. High reliability -Reliability tests comply with AEC-Q200 |

| 8. Operating temperature-55~+125℃(Including self - temperature rise) |

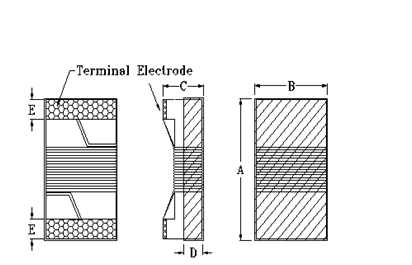

| Size | A | B | C | D | E |

| SWI0603 | 1.80 max. | 1.20 max. | 1.20 max. | 0.38 ref. | 0.35±0.10 |

| SWI0805 | 2.40 max. | 1.60 max. | 1.40 max. | 0.51 ref. | 0.44±0.10 |

| SWI1008 | 2.92 max. | 2.79 max. | 2.20 max. | 1.20 ref. | 0.55±0.10 |

| SWI | 1008 | U | V | - | 10N | J |

| A | B | C | D | E | F |

A: Series

B: Dimension LxW

C: Material

D: Category Code V=Vehicle

E: Inductance 10N=10nH

F: Inductance Tolerance G=±2%, J=±5%, K=±10%

| Part Number | Inductance | Tolerance | Test Frequency (Hz) | Q min. | Rated Current | DCR | SRF |

|---|---|---|---|---|---|---|---|

| SWI0603V-2N0□ | 2 | C,S | 0.1V/250M | 13 | 700 | 0.07 | 8000 |

| SWI0603V-3N9□ | 3.9 | C,S | 0.1V/250M | 22 | 700 | 0.07 | 6900 |

| SWI0603V-4N7□ | 4.7 | C,J,K | 0.1V/250M | 20 | 700 | 0.12 | 5800 |

| SWI0603V-6N8□ | 6.8 | C,J,K | 0.1V/250M | 27 | 700 | 0.08 | 5800 |

| SWI0603V-8N2□ | 8.2 | C,J,K | 0.1V/250M | 30 | 700 | 0.13 | 4200 |

| SWI0603V-10N□ | 10 | J,K | 0.1V/250M | 31 | 700 | 0.13 | 4800 |

| SWI0603V-12N□ | 12 | J,K | 0.1V/250M | 35 | 700 | 0.13 | 4000 |

| SWI0603V-15N□ | 15 | J,K | 0.1V/250M | 35 | 700 | 0.13 | 4000 |

| SWI0603V-18N□ | 18 | J,K | 0.1V/250M | 35 | 700 | 0.16 | 3100 |

| SWI0603V-22N□ | 22 | J,K | 0.1V/250M | 38 | 700 | 0.23 | 3000 |